Study and evaluation of real production needs and consequent production of customized equipment based on customer specifications. Customized solutions for lacquer/electrostatic powder seam protection systems and curing ovens for 3-piece cans, aerosol cans, pails and drums.

-

-

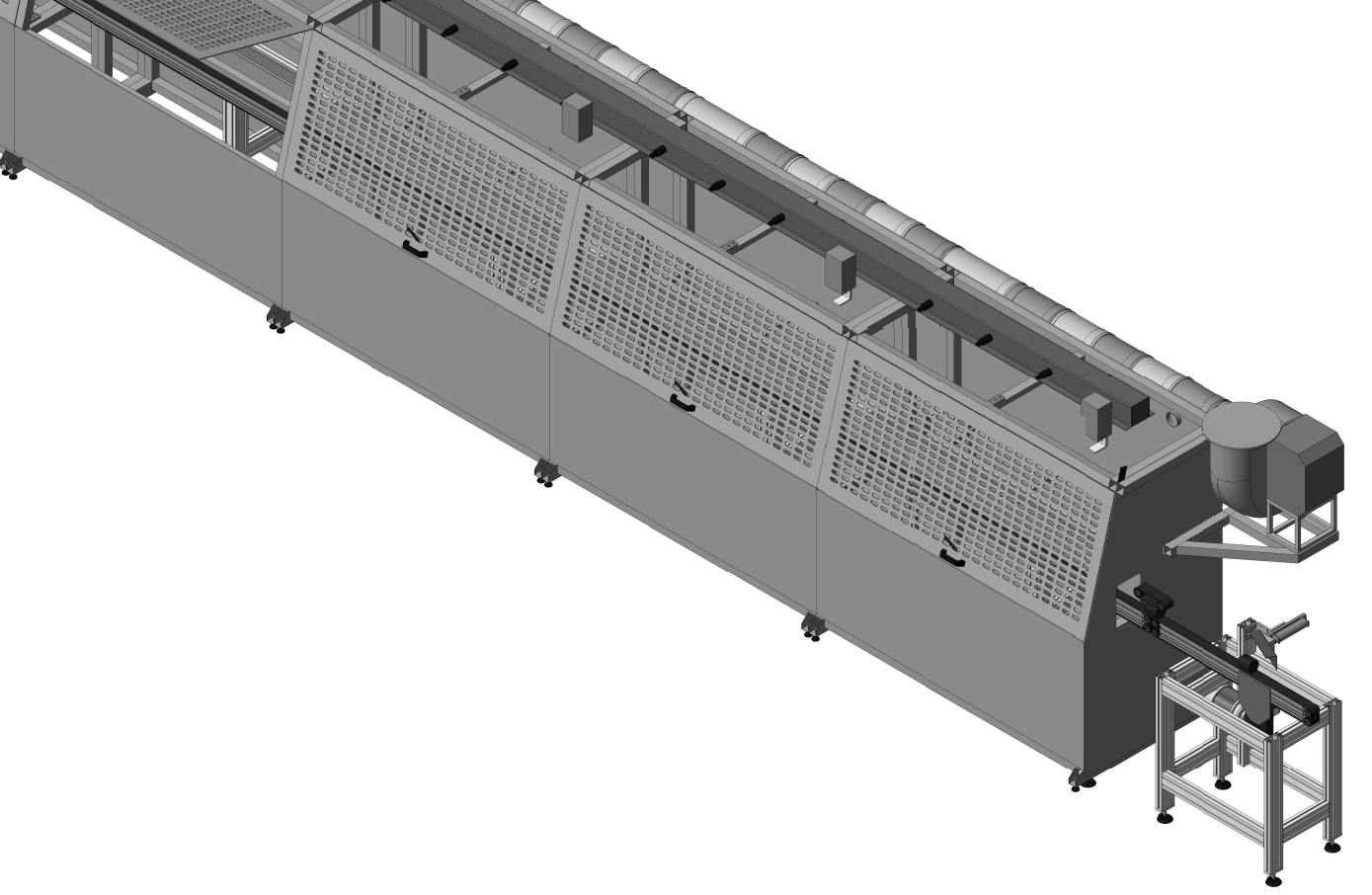

CURING OVENS

Complete curing lines suitable to perform the polimerization process of lacquer and powder coating used to protect the welded seam both inside and outside of 3-piece metal containers such as cans, aerosol cans, pails, drums.

MEPALINE curing systems consist of heating modules powered by gas or electricity, and are suitable to comply with any production capacity, while being designed to match customers layout requirements.In order to offer the maximum operating flexibility, every single heating module is separately controlled for both temperature setting and on/off mode. Metal containers are transported by metal chain or special fabrics belt, whose consistent and long lasting performance are guaranteed by an integrated cooling system and emergency stop-line safety features.

Heating process fumes are collected and exhausted by an on-board centralized collection system.The control of the whole curing line is performed by a state-of-the-art software, which can be easily programmed and managed by the line operator via its intuitive touch screen panel interface.

-

-

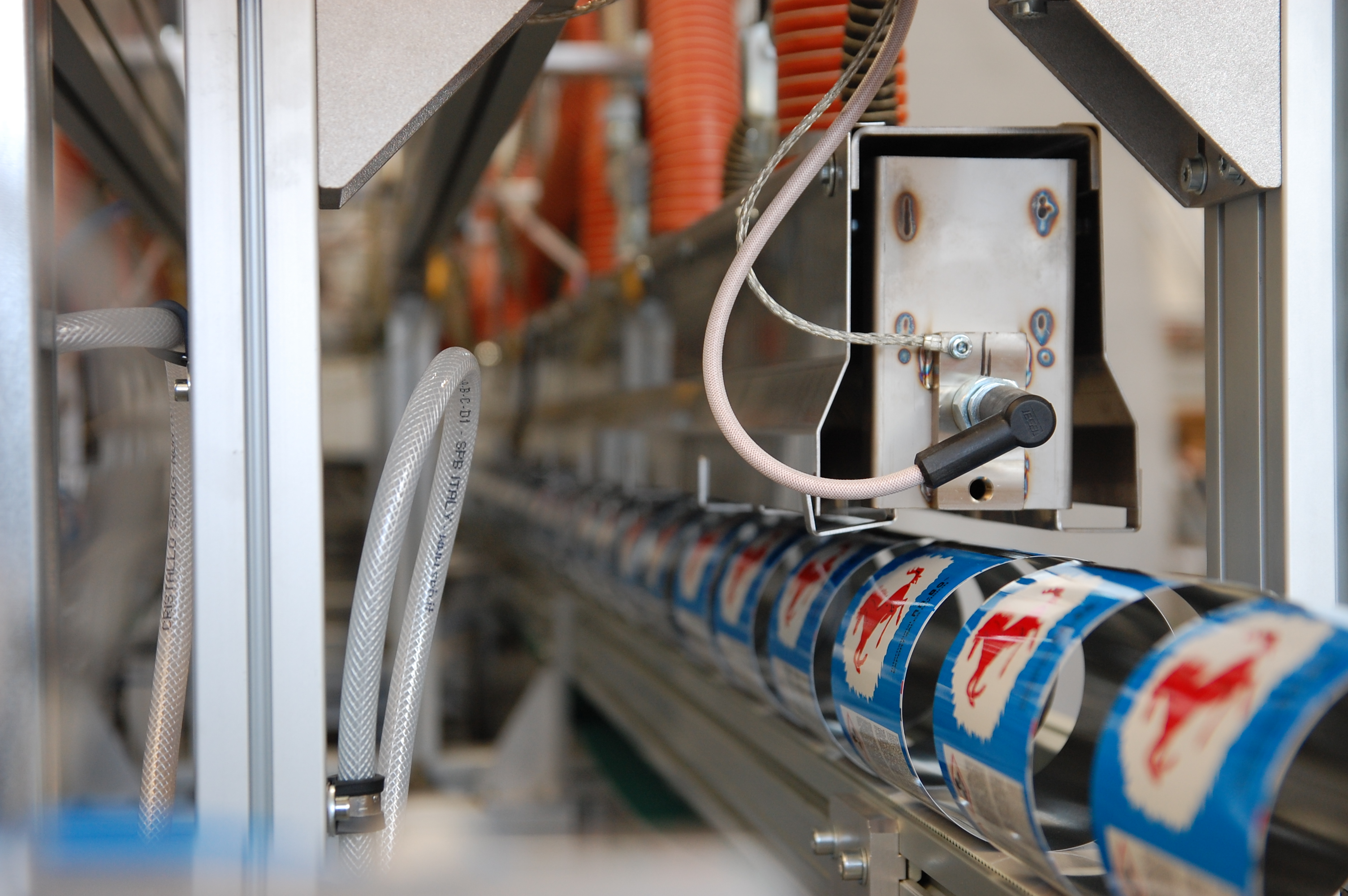

ELECTROSTATIC POWDER APPLICATION SYSTEM SAPE -

90

MEPALINE new Electrostatic Application System is suitable for the protection of inside welded seam protection of 3-piece metal containers for both food and general line manufacturers.

Every single component has been designed to offer maximum operating efficiency, whilst providing extreme process consistency and powder application quality: top requirements of any production line.

The design and manufacturing of this complete unit, are the result of many years of field experience and deep knowledge of this specific process. The extreme simplicity of fine tuning adjustment, a considerable versatility of use and a limited maintenance requirements are the undisputed advantages in operating MEPALINE SAPE – 90 system.

-

-

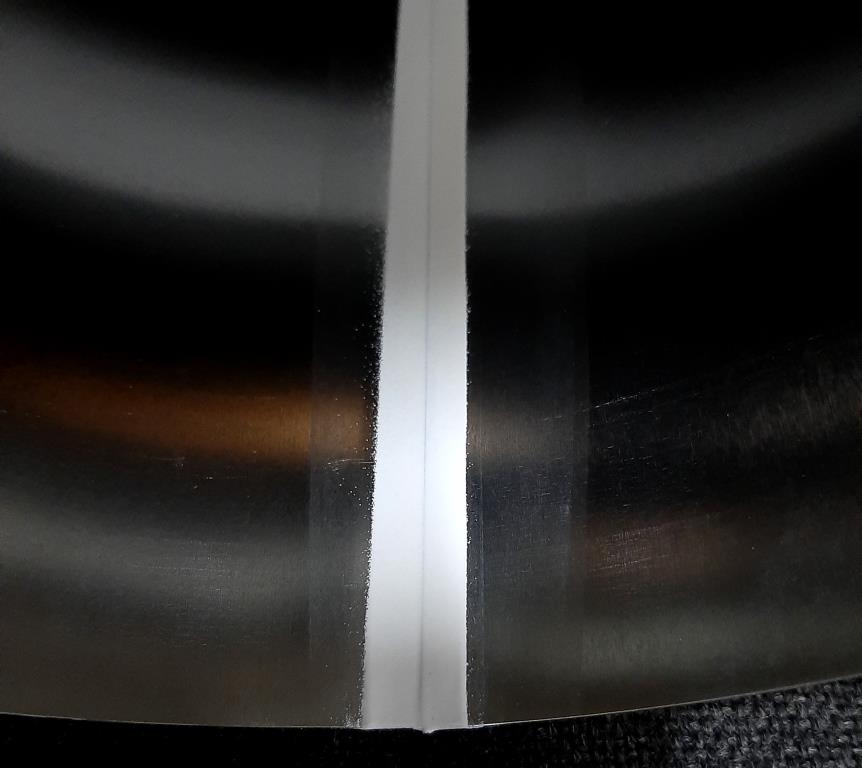

EARS PROTECTION SYSTEM ON PAILS

AUTOMATIC EARS PROTECTION SYSTEM FOR PAILS TYPE MEPALINE "REPAIR"

MEPALINE "REPAIR" system is a dedicated unit suitable to perform welded plug protection by LAQUER or ELECTROSTATIC POWDER on the inside of the pail. This fully automatic equipment can be integrated in any existing or new production line. This system, complete with indexing station and all the necessary suitable conveyor sections, performs the required application either by pad, airspray or electrostatic powder, following customer specification and according to the line capacity.A control panel allows the operator to set and manage accurately all process steps and functions, in compliance to the production line capacity.MEPALINE REPAIR system can be integrated to a dedicated and specifically designed MEPALINE heating unit to allow proper curing of applied protection material.